Our Services

We help metalworking shops adopt automation that delivers real results on the shop floor. Our focus is practical, flexible automation that improves consistency, quality, and throughput—without disrupting existing workflows or replacing skilled trades.

Primary Services

Metalworking Automation

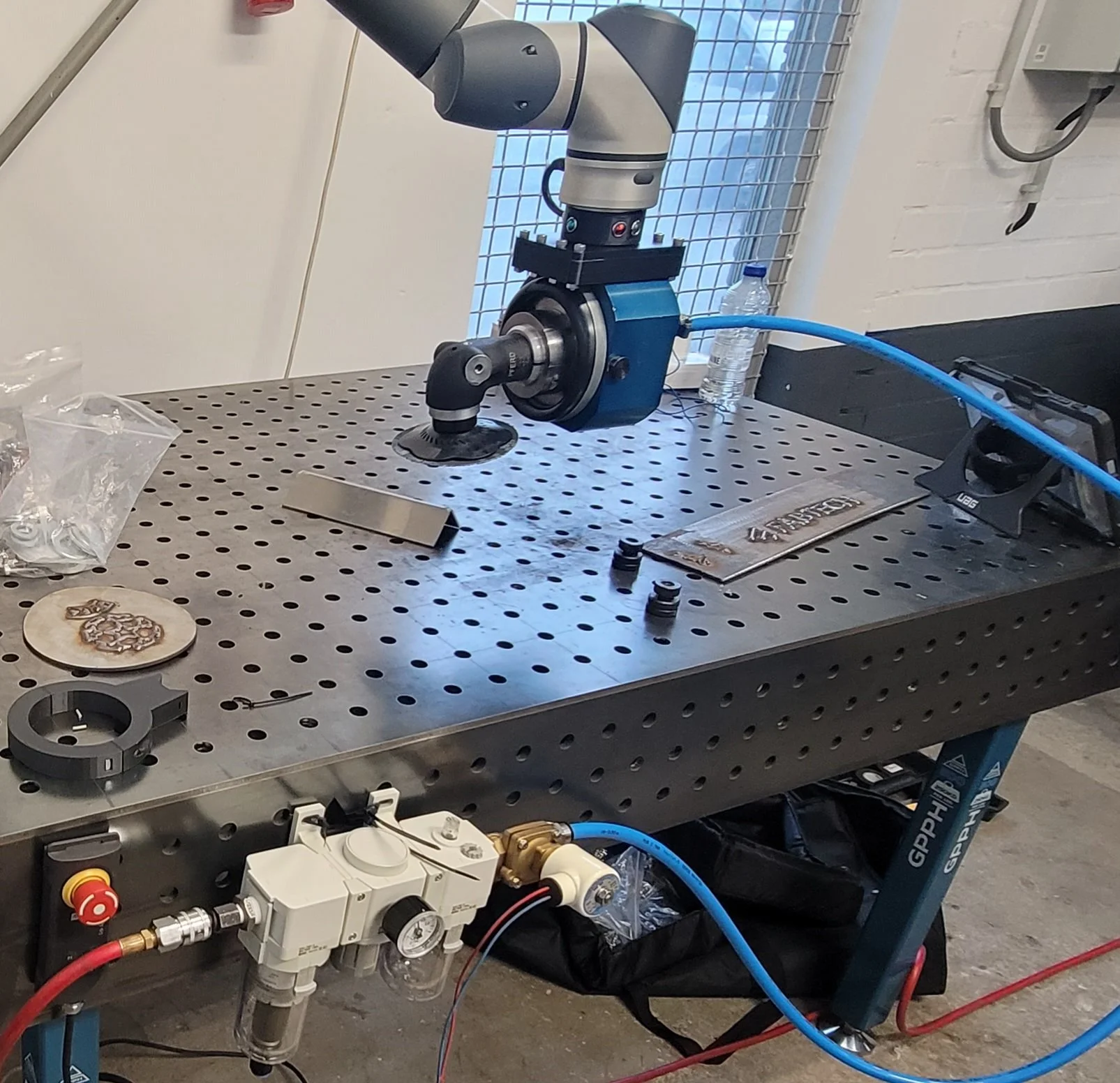

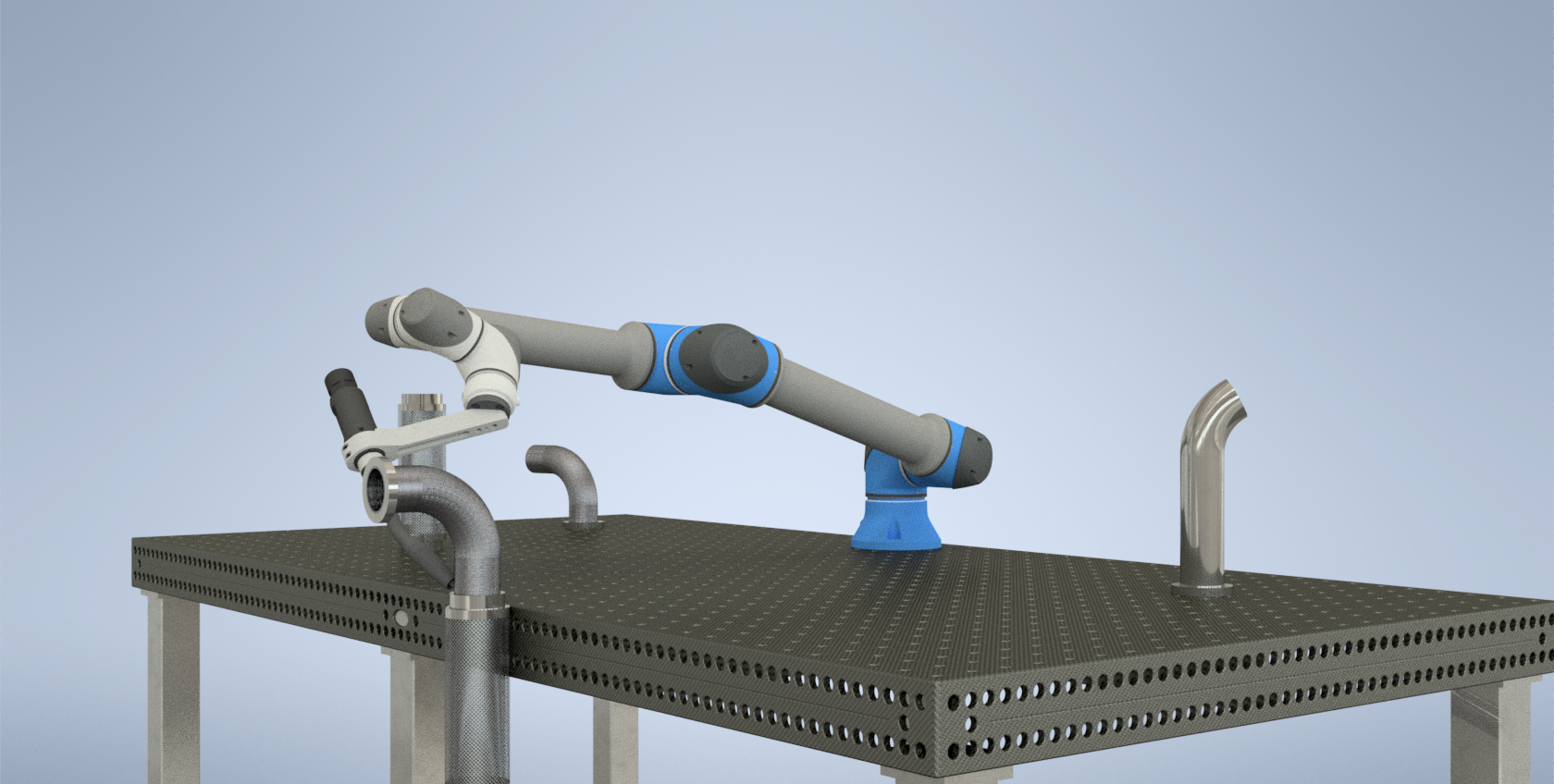

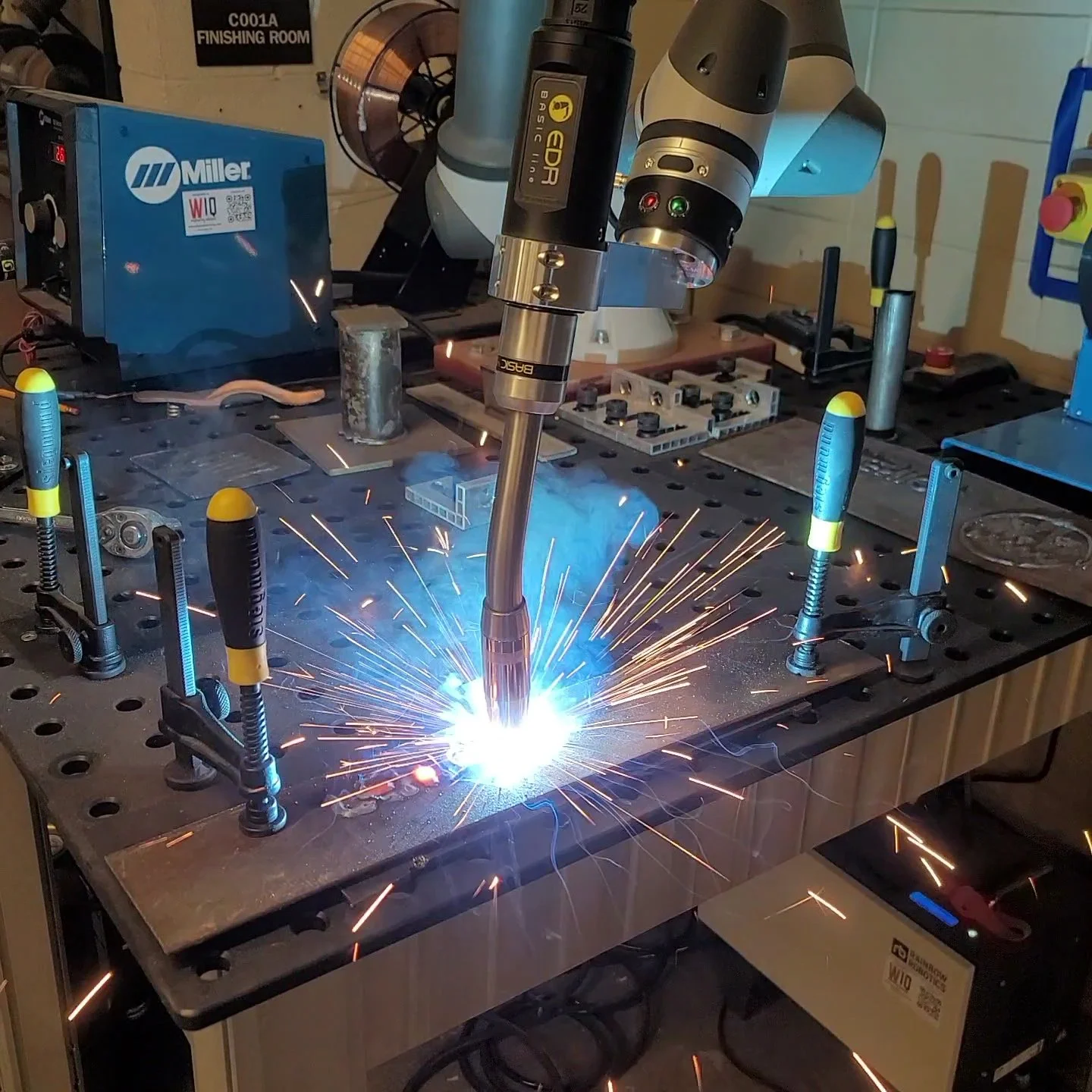

Welding/Grinding/Cutting Cobot Integration

We design and integrate collaborative welding systems specifically for fabrication and job-shop environments including your existing equipment. We can integrate your existing welding machine so your installation is more cost effective. Our approach prioritizes repeatability, consistent weld quality, and ease of use over theoretical cycle-time optimization. Systems are configured to work alongside skilled welders, reducing fatigue and variability while preserving craftsmanship. Integration includes cell layout, safety considerations, weld process selection, and commissioning. Grinding and plasma cutting is available as well.

Automation Readiness Assessments

Before recommending automation, we evaluate whether it truly makes sense for your operation. This includes reviewing part geometry, tolerances, volume, variability, fixturing requirements, and downstream processes. The outcome is a clear, honest assessment of where automation will deliver value—and where manual processes are the better choice. This prevents costly investments that don’t align with real production needs. Start with the survey here.

Low-Volume & High-Mix Automation

Many shops assume automation only works for long production runs. We specialize in flexible automation strategies that accommodate short runs, frequent changeovers, and part variation. This includes adaptable fixturing, efficient programming methods, and workflows designed to minimize setup time—making automation viable even in high-mix environments.

Fixture & Positioner 3D Design for Automation

Reliable automation depends on repeatable part presentation. We design and engineer fixtures and positioners that reduce variability, improve access, and support consistent weld quality. Designs are developed with operator ergonomics, changeover efficiency, and future scalability in mind—so automation becomes predictable instead of frustrating.

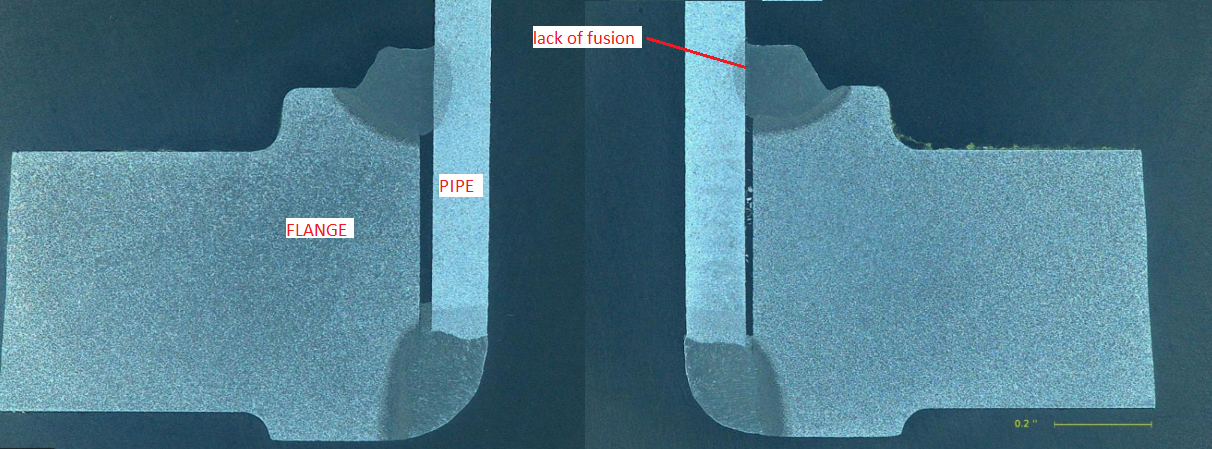

Process Development & Weld Parameter Optimization

Automated welding success depends on a stable, well-defined process. We develop and optimize weld procedures (WPS & PQR) for automated and semi-automated applications, focusing on arc stability, bead profile, penetration consistency, and tolerance to minor part variation. The goal is reducing rework and quality escapes while maintaining robust production performance.

Simulation & Digital Validation (FEA / CFD)

Simulation is used to reduce uncertainty in automated systems. We apply finite element and thermal analysis to validate structures, fixtures, and process effects before fabrication. This helps identify potential issues early and supports informed engineering decisions.

Quality, Consistency & Rework Reduction

Automation is a powerful tool for improving consistency—but only when applied correctly. We analyze process variability, weld defects, and repeatability challenges to help reduce rework, scrap, and operator fatigue through smarter automation and process design.

Education & Workforce Enablement

Cobots are most effective when operators trust and understand them. We provide hands-on training and knowledge transfer to help teams confidently operate, program, and support automated welding systems. The goal is workforce empowerment, not displacement.

Why wIQ Engineering

We come from custom equipment, fabrication, and job-shop environments—not high-volume production lines. Our solutions are grounded in practical engineering, honest assessments, and automation that works under real shop conditions.