Cobots for Welding Education & Workforce Training

Hands-on automation training that complements skilled welding — not replaces it.

Modern manufacturing is changing, but the fundamentals of welding skill remain critical. Collaborative welding robots (cobots) help students learn consistency, repeatability, and process discipline while still respecting the craft of welding.

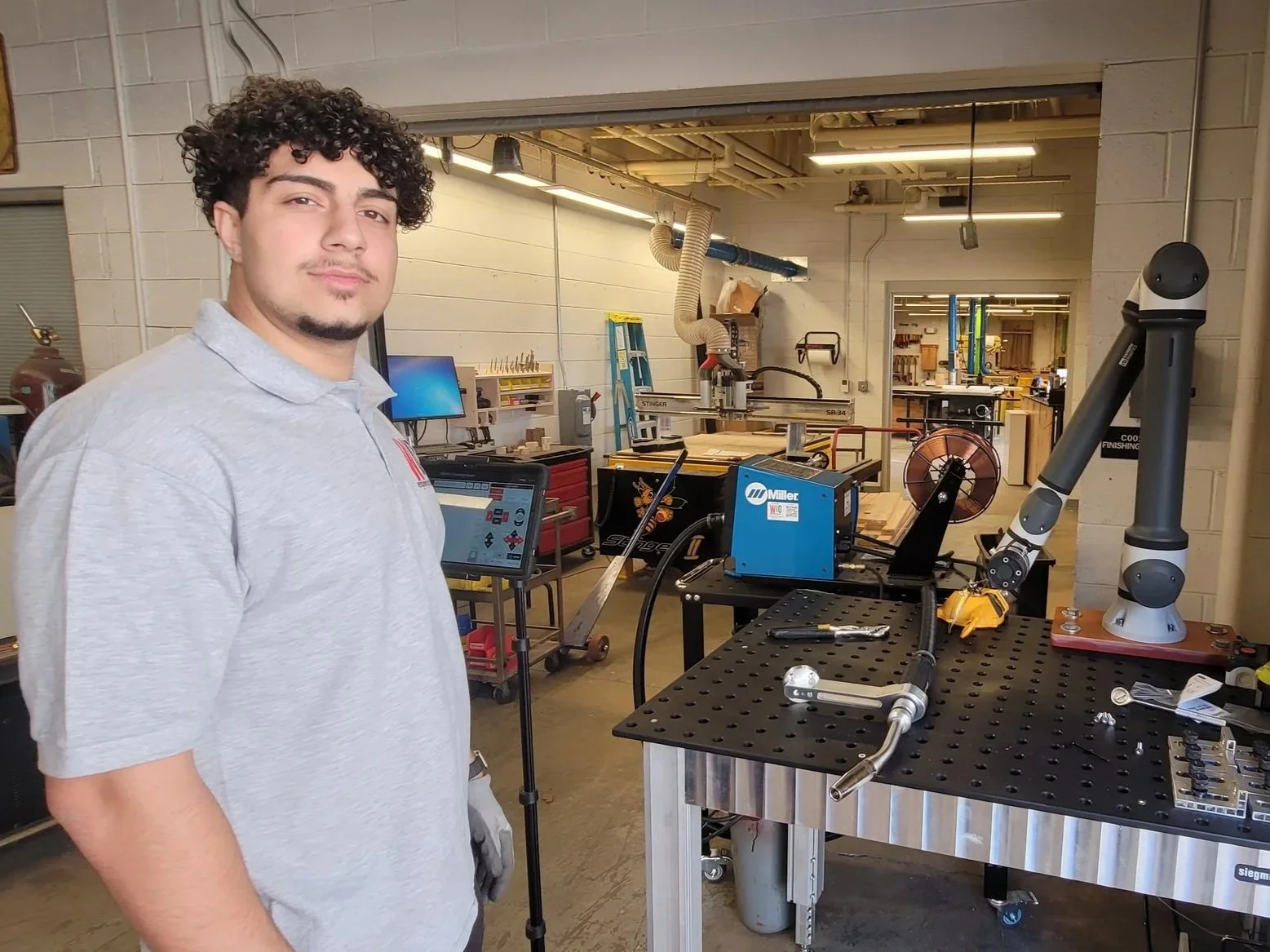

At wIQ Engineering, we work with educational institutions to introduce cobot welding in a practical, instructor-friendly, classroom-ready way. Similar to the one we did at Lehigh University Design Labs.

Why Cobots Belong in Welding Education

Cobots are not a substitute for skilled welders. They are a teaching tool.

In an educational setting, cobots help students:

See the impact of torch angle, travel speed, and stick-out

Understand repeatability and process control

Experience real-world shop conditions they will encounter after graduation

Build confidence working with automation instead of fearing it

Cobots don’t replace welders. They amplify skilled welding.

What We Offer Educational Institutions

Turnkey Cobot Welding Training Cells

Classroom-ready collaborative welding systems

MIG or TIG configurations

Designed for safety, visibility, and small lab footprints

Easy to integrate into existing welding programs

Curriculum & Instructor Support

Structured lesson plans from introductory to advanced topics

Lab exercises focused on:

weld quality

repeatability

fixture sensitivity

tolerance awareness

Instructor onboarding and hands-on training

Rental & Pilot Programs

Semester-based or short-term rentals

Ideal for:

new programs

grant-funded pilots

workforce development initiatives

Try cobot welding without a full capital commitment

Grant & Funding Support

Assistance with technical scope and justification

Experience supporting:

CTE programs

state workforce grants

federal and foundation-based funding

We help align equipment goals with funding requirements

Who This Is For

Our educational cobot programs are designed for:

Community colleges

Technical and vocational schools (CTE)

Universities with manufacturing, mechanical, or mechatronics programs

Workforce development and retraining centers

Whether you are introducing automation for the first time or expanding an existing lab, we tailor the approach to your program’s goals.

What Students Gain

Students trained on collaborative welding systems graduate with:

Exposure to real shop automation environments

A stronger understanding of process consistency

Improved awareness of:

fixture setup

tolerance sensitivity

repeatable weld quality

Increased confidence entering modern fabrication and manufacturing shops

This experience helps students transition faster and contribute sooner in industry roles.

Industry Alignment

Local manufacturers increasingly expect graduates to have basic automation awareness, even if manual welding remains a core skill.

Cobot exposure in education:

Reflects what students will see in modern job shops

Aligns training with regional manufacturing needs

Strengthens connections between schools and industry partners

Students trained on collaborative systems adapt faster in today’s production environments.

How We Work With Schools

Our engagement process is straightforward:

Program discussion

Understand goals, space, curriculum, and budgetDemonstration

On-site or hosted demo of a classroom-ready cobot systemPilot or deployment

Rental, pilot program, or full system integrationOngoing support

Instructor assistance, curriculum updates, and technical guidance

We stay involved beyond delivery to ensure the program is successful.

Let’s Talk About Your Program

Whether you are building a new automation module or enhancing an existing welding curriculum, we can help you introduce cobot welding in a way that fits your institution.

👉 Email us about adding cobots to your program

Serving community colleges, technical schools, universities, and workforce programs with practical automation solutions.